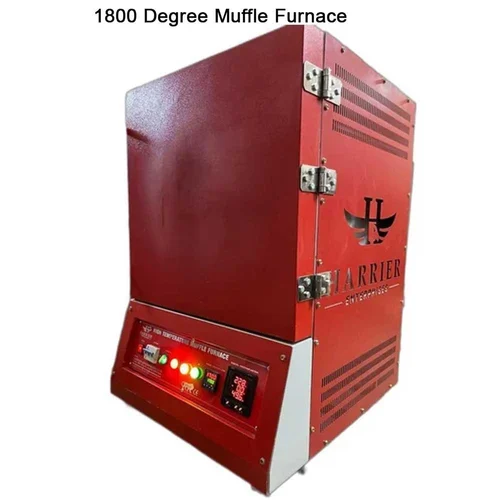

Harrier Enterprises is a prominent manufacturer and supplier of vacuum furnaces and other thermal processing equipment in India. Established in 2015, the company specializes in producing a variety of furnaces, including muffle furnaces, vacuum furnaces, and industrial ovens. Their products are designed to meet the rigorous demands of industries such as aerospace, electronics, automotive, and pharmaceuticals.

The company’s vacuum furnaces are engineered for high-temperature applications requiring a controlled atmosphere to prevent oxidation and contamination during heat treatment. Harrier Enterprises emphasizes quality and innovation, ensuring that their furnaces are equipped with advanced features like PID temperature control for precise thermal management.

Harrier Enterprises is committed to customer satisfaction, offering tailored solutions and comprehensive support from installation to maintenance. They hold several certifications, including ISO 9001:2015 and CE certification, reflecting their dedication to quality standards and safety compliance. With a focus on cost-effectiveness without compromising performance, Harrier Enterprises positions itself as a reliable partner for businesses seeking efficient thermal processing solutions in India.

A vacuum furnace is an advanced thermal processing system designed to operate in a low-pressure or vacuum environment, minimizing oxidation and contamination during heat treatment processes. This specialized furnace is widely used in industries such as aerospace, electronics, and metallurgy for applications like brazing, sintering, and heat-treating materials under controlled conditions. By removing air and other reactive gases, the vacuum environment prevents unwanted reactions, ensuring high-purity results. Vacuum furnaces provide precise temperature control and uniform heating, making them essential for manufacturing processes that demand a clean and controlled atmosphere for the thermal treatment of materials.

| Material Loading Capacity (Kg) | 1-500 Kg |

| Power Source | Electric |

| Automation Grade | Semi-Automatic |

| Rated Power (KW) | 12 KW |

| Voltage (V) | 240 V |

| Melting Time (Min) | 120 Min |

| Max Operating Temperature (°C) | 1700 °C |

| Heater Type | Mosi2 Rod |

| Heating Zone (mm) | 200+200+200=600mm |

| Temperature Precision (°C) | ±1 |

| Thermocouple Type | B Type |

| Electrical Requirements | 220-240VAC, 50/60Hz, single phase |

| Min Working Temperature (°C) | Ambient |

| Max Working Temperature (°C) | 1400°C / 1300°C |

| Refractory Lining | Mitsubishi high quality 1600 grade fiber alumina |

| Heating Element Type | Silicon carbide (SiC) |