Tube Furnace Manufacturers

A tube furnace manufacturer is a type of laboratory furnace that has a chamber that can be divided into two or more sections. This allows for the independent heating of different samples or the use of different atmospheres in different sections of the furnace.

Tube furnaces are typically used for applications that require precise temperature control where the use of different atmospheres is necessary. Some common applications for split tube furnaces include: Split tube furnaces are available in a variety of sizes and temperature ranges. The size of the furnace will determine how many samples can be heated at once, while the temperature range will determine the types of materials that can be heated in the furnace. When choosing a split tube furnace, it is important to consider the size of the furnace, the temperature range, the type of controller, and the price. The furnace should also be compatible with the type of materials that will be heated in it.

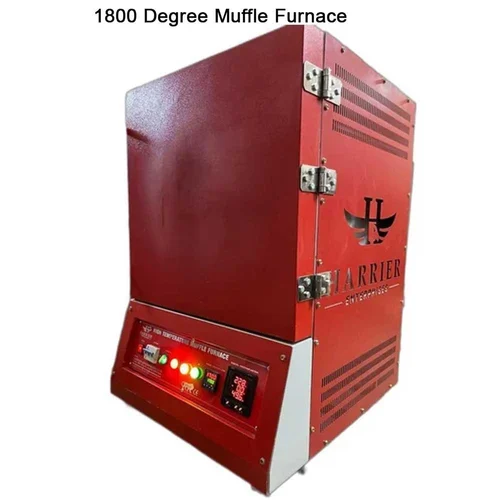

Harrier Enterprises offers high-quality tube furnaces designed for precise heating applications across industries. Our tube furnaces provide uniform temperature distribution, excellent thermal efficiency, and reliable performance for processes such as material testing, heat treatment, and research applications. With advanced features like digital temperature control, robust construction, and energy-efficient operation, our tube furnaces ensure optimal results. Available in different sizes and configurations, they cater to diverse industrial needs. Trust Harrier Enterprises for durable and high-performance tube furnaces that meet international standards. Contact us today to learn more about Harrier Enterprises.

Enquiry Now

Frequently Asked Questions (FAQs)

What is a tube furnace?

A tube furnace is a type of high-temperature furnace designed with a cylindrical, elongated heating chamber or tube. It is commonly used for applications that require precise temperature control and uniform heating of materials.

What are the typical applications of tube furnaces?

Tube furnaces are used in a wide range of applications, including materials research, crystal growth, chemical vapor deposition (CVD), thermal processing of samples, annealing, sintering, and more.

How does a tube furnace work?

Tube furnaces heat materials by surrounding them with a heating element, such as resistance wire or graphite, located within the cylindrical chamber. The temperature is controlled by regulating the power supplied to the heating element. Inert gases or controlled atmospheres can be introduced to create specific conditions.

What is a split tube furnace?

A split tube furnace is a type of high-temperature furnace that consists of a cylindrical heating chamber with a split design. This split allows for easy insertion and removal of samples or materials to be heated. It is commonly used for controlled heating, annealing, and sintering processes.

What are the primary applications of split tube furnaces?

Split tube furnaces are versatile and can be used for a wide range of applications, including materials research, crystal growth, ceramics processing, and thermal testing of various materials and components.

How does a split tube furnace work?

A split tube furnace typically uses electric heating elements, often made of resistance wire, to generate high temperatures inside the heating chamber. The sample or material to be heated is placed within the split section, and the furnace is controlled to maintain the desired temperature profile.

What is the maximum temperature that a split tube furnace can reach?

The maximum temperature a split tube furnace can achieve varies depending on the specific model and design. Some furnaces can reach temperatures exceeding 1,800°C (3,272°F), while others are designed for lower-temperature applications.

Can split tube furnaces be used for vacuum or controlled atmosphere processes?

Yes, some split tube furnaces are designed to work under vacuum or controlled atmosphere conditions. These furnaces may have options for gas flow control or vacuum pumping to create specific environments within the heating chamber.

What maintenance is required for split tube furnaces?

Regular maintenance includes cleaning the furnace chamber, checking the heating elements for wear, and calibrating the temperature controller if necessary. Maintenance requirements may vary by manufacturer and model, so it’s essential to consult the user manual for specific guidance.