What is a Muffle Furnace

A muffle furnace is a specialized type of laboratory furnace designed to heat materials to high temperatures in a controlled environment. It is characterized by its insulated chamber, known as a muffle, which separates the heating elements from the material being processed. This design prevents contamination of the samples by combustion products, ensuring a clean heating process.

Muffle Furnace Principle:

The working principle of a furnace involves indirect heating through a controlled environment, primarily utilizing electric heating elements.

Applications

- Metallurgy: Used for heat treatment processes like annealing and hardening metals.

- Ceramics and Glass: Ideal for sintering and melting processes.

- Biomedical: Employed in the analysis of materials and drug testing.

- Pharmaceuticals: Used for ashing and quality control of samples.

- Environmental Testing: Analyzing ash content in materials and conducting water quality assessment.

Uses of a Muffle Furnace:

Muffle furnaces are commonly used for:

- Material Testing – Analyzing ash content, thermal expansion, and tensile strength of metals and ceramics.

- Heat Treatment – Used for annealing, tempering, and hardening materials to alter their properties.

- Calcination and Sintering – Often employed in the production of ceramics, glass, and composites by heating raw materials to high temperatures.

- Ash Testing – Determining ash content in substances, such as in food and coal analysis.

- Incineration – Safe burning of small samples to leave behind only ash for analysis, used in fields like forensics and pharmaceuticals.

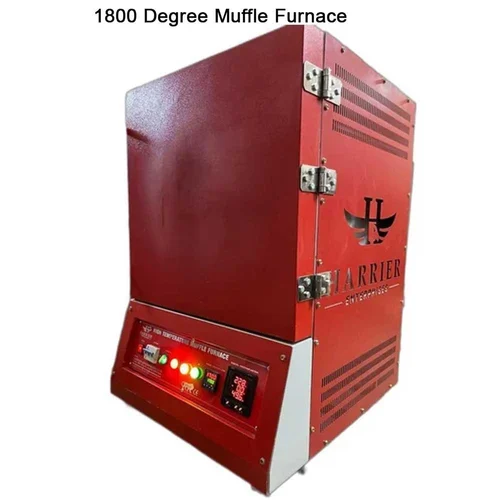

Features of a Muffle Furnace:

- High-Temperature Capabilities: Operates up to 1700°C or more, depending on the model.

- Insulated Chamber: Maintains uniform temperature and isolates samples from direct contact with heating elements.

- Programmable Controls: Precise temperature control and timers for process automation.

- Rapid Heating and Cooling: Some models offer quick temperature ramp-up and cooldown for efficiency.

- Robust Construction: Often made with corrosion-resistant materials for durability in high-temperature environments.

Working Principle of a Muffle Furnace:

The muffle furnace operates by using heating elements, such as silicon carbide or nichrome wires, which line the walls of the chamber. When electrical current flows through these elements, they generate heat, which transfers through the chamber lining into the insulated space where samples are placed. The insulated chamber minimizes heat loss and maintains a steady, even temperature distribution, allowing precise control over the heating process without contaminating the sample.

Benefits of a Muffle Furnace:

- High Precision and Control: Accurate temperature management with minimal fluctuations.

- Reduced Contamination: An isolated chamber prevents sample contamination from direct heat exposure.

- Versatile Applications: Suitable for a wide range of scientific, industrial, and manufacturing tasks.

- Energy Efficiency: Insulation retains heat effectively, reducing power consumption.

- Enhanced Safety: The insulated chamber reduces external heat, making it safer to operate.