Muffle Furnace Manufacturers

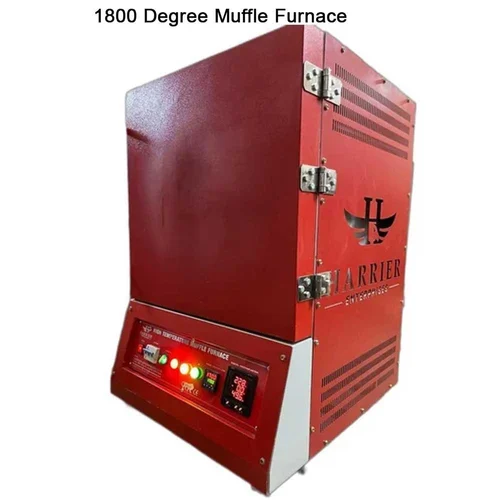

Harrier Enterprises is a top manufacturer of laboratory and industrial muffle furnace manufacturers and suppliers in India. With a decade of expertise in thermal engineering, the company offers a comprehensive selection of furnaces to customers worldwide. Evidence of their dedication to quality design, superior products, and affordability can be seen in the satisfaction of over 30 countries’ customers.

A muffle furnace or electric muffle oven is extremely important equipment in a laboratory for all kinds of heat treatment experiments. A furnace is very similar to a greenhouse and is used, mainly in chemistry laboratories, when there is a need for very high temperatures to 1800°C in the calcination of substances. The heating furnace consists of a metallic chamber, its coating being composed of refractory material.

Harrier Enterprises offers high-quality and high-temperature heating furnaces and is available in the temperature ranges of 1000°C, 1200°C, 1400°C, 1700°C, and 1800°C, etc.

Types of Muffle Furnace

| Brand | Harrier Enterprises |

| Material Loading Capacity | 600 Kg |

| Chamber Size (mm X mm X mm) | 4 inch x 4 inch x 9 inch |

| Max Temperature (C) | 1100 Deg C |

| Type of Model | Laboratory |

| Features | Digital Display |

| Power Source | Electric |

| Voltage | 240 V |

| Power | 5000 Watt |

| Minimum Order Quantity | 1 |

Harrier Enterprises is a prominent manufacturer and supplier of the best muffle furnace price in India, specializing in high-quality thermal processing equipment. Muffle furnaces are essential for applications, including metal heat treatment, ceramics, and material testing, providing controlled environments for precise heating.

Product Features:

- Temperature Range: Harrier Enterprises offers muffle furnaces that can reach temperatures suitable for a variety of industrial processes, ensuring versatility and efficiency.

- Design: Their furnaces are designed to optimize energy consumption while maintaining uniform temperature distribution, which is crucial for consistent results in thermal applications.

- Safety Standards: The company adheres to stringent safety standards, incorporating features that enhance user safety during operation.

Market Position: As a leading player in the muffle furnace market, Harrier Enterprises has established a reputation for reliability and innovation. Their commitment to quality and customer service has made them a preferred choice among industries requiring precision heating solutions.