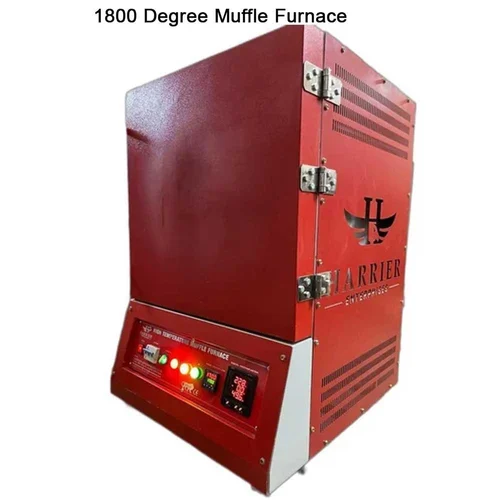

High Temperature Muffle Furnace 1700°C

Harrier Enterprises is a prominent manufacturer and supplier of high temperature muffle furnaces, capable of reaching temperatures up to 1700°C. These furnaces are designed for various applications.

High Temperature Muffle Furnace Features

- High-Temperature Capability: The muffle furnace can achieve temperatures as high as 1700°C, allowing for the processing of a wide range of materials that require intense heat for effective results.

- Precision Control: Equipped with advanced PID temperature controllers, these furnaces ensure accurate temperature regulation, essential for consistent and reliable outcomes in scientific experiments.

- Insulation: The furnaces feature superior insulation materials, including ceramic wool and mineral wool, which minimize heat loss and enhance energy efficiency.

- Versatility: Harrier Enterprises offers various models tailored to specific needs, including laboratory muffle furnaces and industrial applications.

1700°C High Temperature Muffle Furnace (Box Type Resistance Furnace) Mainly Provides High Temperature Heat Treatment Environment For Industrial Colleges, Research Institutes, Factories, and Other Industrial Laboratories, And Is Applied To New Materials Such As Metal Materials, Ceramic Materials, Nano Materials, And Semiconductor Materials.

A high-temperature muffle furnace is a specialized heating device used in laboratories and industrial settings to achieve extremely high temperatures for various purposes such as material testing, heat treatment, ashing, and ceramic or glass production.

The high-temperature muffle furnace is utilized across multiple industries such as aerospace, pharmaceuticals, and metallurgy. Its ability to provide a controlled environment prevents contamination and ensures the integrity of the materials being processed. With a commitment to quality and innovation, Harrier Enterprises continues to deliver reliable heating solutions that meet the evolving demands of the industry.

| Model | HE-MF-1700p |

| Maximum Temp | 1700°C |

| Working Temp | 1600°C |

| Temp Accuracy | 1°C |

| Heating Elements | Molybdenum Disilicide Heating Element Easily Replaced (MoSi2) |

| Power Supply | 220 / 415 Volts 3 phases And Single Phase AC Supply |

Enquiry Now

Frequently Asked Questions (FAQ)

What is a high-temperature muffle furnace?

A high-temperature muffle furnace is a specialized heating device designed to reach and maintain high temperatures within a controlled environment. It’s commonly used in laboratories and industrial settings for processes like sintering, calcination, and heat treatment of materials.

How does a muffle furnace work?

A muffle furnace works by heating a heating element (often made of resistant materials like Kanthal) to generate intense heat. The heating element is enclosed in a chamber called the muffle, which provides insulation and maintains the desired temperature. The material to be heated is placed inside the muffle, and the furnace is programmed to reach and maintain the required temperature.

What are the typical operating temperatures of a high-temperature muffle furnace?

High-temperature muffle furnaces can reach temperatures ranging from 1000°C to 1800°C (1832°F to 3272°F) and sometimes even higher, depending on the model and design. The temperature range varies based on the specific furnace and its intended applications.

What are the applications of a high-temperature muffle furnace?

High-temperature muffle furnaces find applications in various fields, including materials science, ceramics, metallurgy, pharmaceuticals, and research. They’re used for processes such as annealing, ashing, sintering, roasting, and heat treatment of materials.

What types of materials can be processed in a high-temperature muffle furnace?

Materials like metals, ceramics, glass, and other heat-resistant substances can be processed in a high-temperature muffle furnace. These furnaces are especially useful for processing materials that require high-temperature treatments for transformation or modification.

What safety precautions should be taken when operating a high-temperature muffle furnace?

Safety precautions include using appropriate personal protective equipment (PPE) like heat-resistant gloves, safety goggles, and lab coats. Ensure proper ventilation, follow manufacturer instructions, and be cautious when handling hot materials or opening the furnace after a heating cycle.

How do I choose the right high-temperature muffle furnace for my application?

Consider factors such as the required temperature range, chamber size, heating rate, control options (e.g., programmable controllers), and the types of materials you’ll be working with. Consulting with a furnace supplier or an expert can help tailor the selection to your specific needs.

Can a muffle furnace be used for both research and industrial applications?

Yes, muffle furnaces are versatile and can be used in both research and industrial settings. They are widely utilized in laboratories for research purposes and in industrial settings for large-scale material processing and production.