What is the difference between muffle furnace and laboratory oven?

Muffle furnaces and laboratory ovens are essential equipment in scientific and industrial settings, but they serve different purposes and operate under distinct conditions. Understanding these differences is crucial for selecting the appropriate equipment for specific applications.

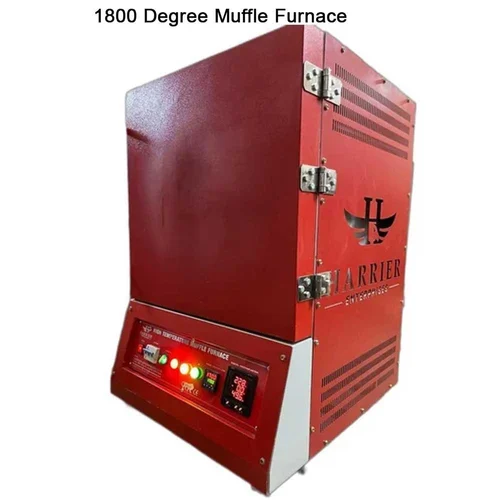

Temperature Capabilities

- Muffle Furnace: Muffle furnaces can achieve very high temperatures, often exceeding 1000°C, with some models reaching up to 1800°C. This makes them suitable for processes such as calcination, sintering, and metal melting.

- Laboratory Oven: In contrast, laboratory ovens typically operate at much lower temperatures, generally below 300°C. They are primarily used for drying materials, sterilizing equipment, and conducting low-temperature heat treatments.

Design and Heating Mechanism

- Muffle Furnace: The design of a muffle furnace includes an insulated chamber that separates the heating elements from the material being processed. This isolation helps prevent contamination from combustion byproducts and allows for uniform heating.

- Laboratory Oven: Laboratory ovens use convection heat, circulating hot air around the chamber. The heating elements are outside the inner chamber, which can lead to uneven temperature distribution if improperly managed.

Applications

- Muffle Furnace: These furnaces are ideal for high-temperature applications such as:

- Melting metals

- Conducting high-temperature chemical reactions

- Performing analytical tests like ash content determination.

- Laboratory Oven: They are better suited for tasks that do not require high temperatures, including:

- Drying samples

- Curing materials

- Sterilizing laboratory instruments.

Safety Features and Operation Environment

- Muffle Furnace: Designed to operate safely in environments where combustible gases may be present, muffle furnaces minimize the risk of combustion by using very little oxygen during operation.

- Laboratory Oven: These ovens have safety features to reduce direct contact with hot surfaces but are not typically designed for use in combustible atmospheres.

Cost Considerations

- Generally, muffle furnaces are more expensive than laboratory ovens due to their advanced design and high-temperature capabilities. The investment in a muffle furnace is justified by its specialized applications and efficiency in handling extreme conditions.

Differences Between Muffle Furnaces and Laboratory Ovens

| Aspect | Muffle Furnace | Laboratory Oven |

|---|---|---|

| Temperature Range | Up to 1,800°C | Up to 300°C |

| Heating Mechanism | Indirect heating with an insulated chamber. | Direct heating with air circulation. |

| Applications | High-temperature processes like ashing. | Low-temperature processes like drying. |

| Structure | Closed chamber with heat-resistant insulation. | Open chamber with adjustable airflow. |

Conclusion

Choosing between a muffle furnace manufacturer and a laboratory oven largely depends on the specific requirements of your application. If high temperatures and precise control over heating conditions are necessary, a muffle furnace is the appropriate choice. For general drying or low-temperature applications, a laboratory oven will suffice. Understanding these key differences ensures that you select the right equipment for your laboratory or industrial needs.